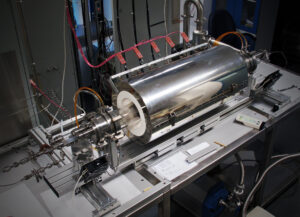

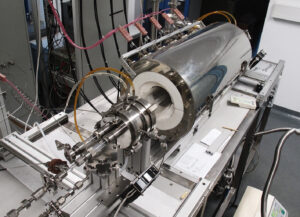

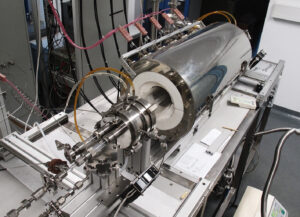

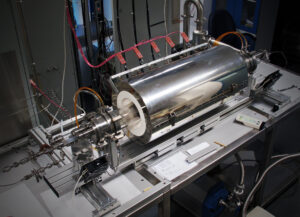

Halide Vapor Phase Epitaxy

Halide Vapor Phase Epitaxy (HVPE) is currently the most common approach for manufacturing the vast majority of commercially available GaN substrates. This technique allows a relatively high growth rate (100-200 μm/h), but suffers from a phenomenon known as parasitic nucleation.